Introduction

In the depths of modern factories, a quiet revolution unfolds. Every sensor reading, every machine vibration, every quality measurement flows into vast data lakes, creating perfect digital mirrors of physical reality. These "world mirrors"—also known as digital twins—represent one of the most profound shifts in how we understand and control complex systems. They're not mere simulations; they're living, breathing digital entities that evolve in perfect synchronization with their physical counterparts, enabling prediction, optimization, and control at scales previously impossible.

The Digital Twin Paradigm

A digital twin is far more than a 3D model or dashboard. It's a complete digital representation of a physical entity that:

- Mirrors real-time state through continuous sensor data

- Simulates future states through physics-based and ML models

- Learns from historical patterns to improve predictions

- Enables intervention through bidirectional control systems

Consider a wind turbine's digital twin: it knows the current wind speed, blade angle, and power output. But it also predicts bearing failure 6 months out, optimizes blade pitch for tomorrow's weather forecast, and coordinates with grid operators to balance supply and demand. The physical and digital become indistinguishable in their coupling.

The Industrial Data Explosion

Modern factories generate staggering amounts of data: - A single automotive plant produces 5TB daily from 50,000+ sensors - Semiconductor fabs track millions of parameters per wafer - Oil refineries monitor thousands of process variables continuously - Smart buildings generate gigabytes from HVAC, lighting, and occupancy sensors

This isn't just "big data"—it's complete data, capturing every measurable aspect of physical processes. The challenge isn't collection but transformation: how do we convert this flood of signals into actionable intelligence?

Palantir's Foundry: The Ontological Approach

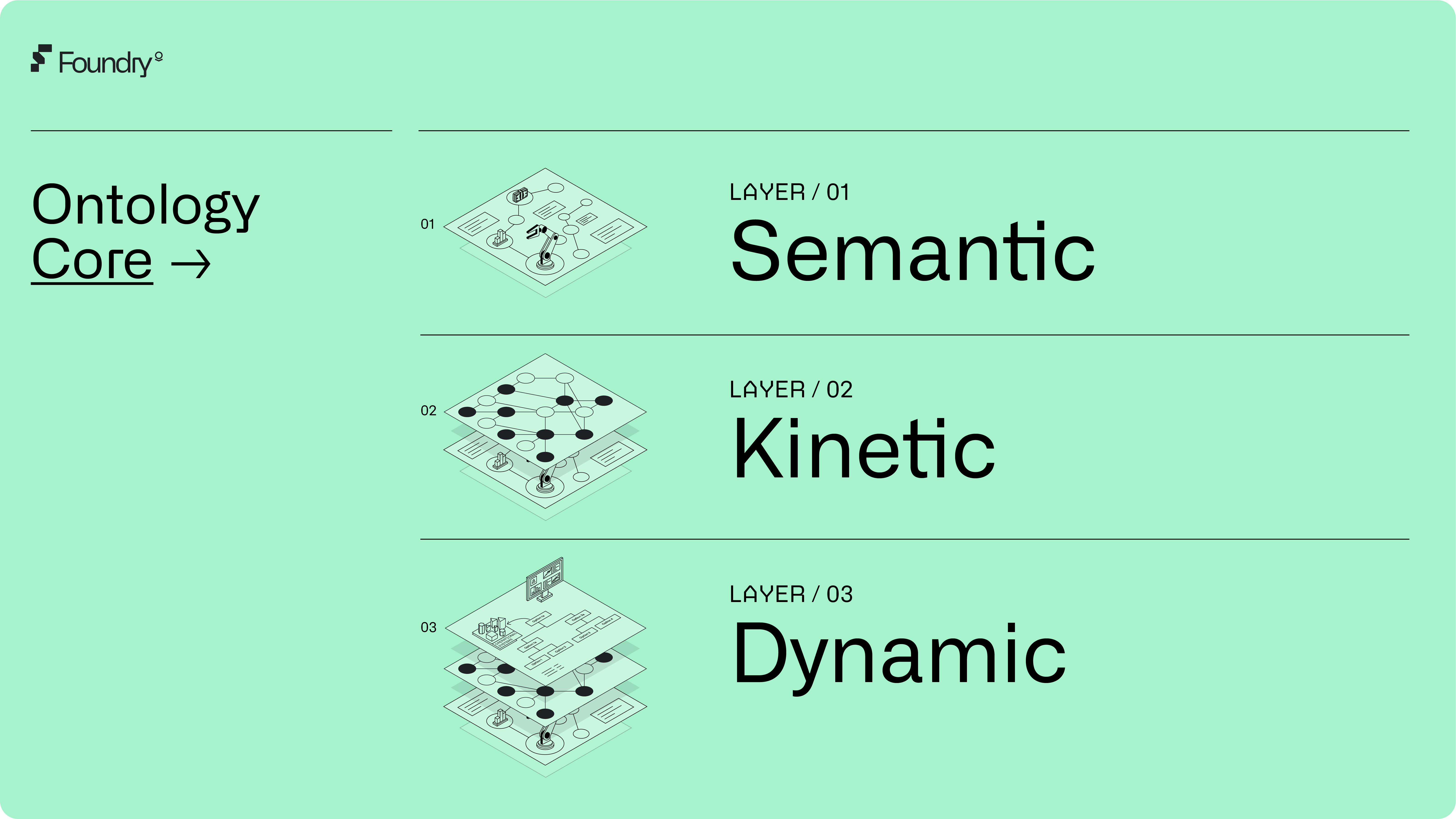

Palantir's Foundry platform exemplifies the world mirror philosophy through its Ontological framework. Rather than treating data as disconnected streams, Foundry builds a semantic model where:

The Ontological Layer

Foundry's Ontology creates a semantic graph that mirrors real-world relationships:

Objects: Digital representations of physical entities (machines, parts, workers, facilities) - Each object has properties mirroring real attributes - Objects maintain relationships reflecting physical connections - State changes propagate through the graph automatically

Actions: Operations that can be performed on objects - Map to real-world processes (start machine, adjust parameters, schedule maintenance) - Include built-in validation and safety constraints - Create audit trails linking digital decisions to physical outcomes

Abstractions: Progressive layers of insight - Raw sensor data → cleaned signals → calculated metrics → KPIs → strategic insights - Each layer adds semantic meaning while preserving lineage - Tautological refinement: each abstraction provably derives from lower levels

The Tautological Pyramid

The power of Foundry's approach lies in its tautological structure—each level of abstraction maintains mathematical proof of its connection to raw data:

- Sensor Layer: Raw voltage/current readings

- Signal Layer: Calibrated physical measurements

- Event Layer: Detected states and transitions

- Process Layer: Workflows and procedures

- Performance Layer: Efficiency metrics and KPIs

- Optimization Layer: Recommended actions and forecasts

- Strategic Layer: Business intelligence and planning

Each transformation is auditable, reversible, and verifiable. A CEO's dashboard showing "15% efficiency gain possible" traces back through every layer to specific sensor readings.

World Mirrors in Practice

BMW's Factory Digital Twin

BMW's Regensburg plant implements a complete digital twin: - 250,000 data points updated every second - Predictive quality control catching defects before they occur - Energy optimization reducing consumption by 25% - Production simulation testing line changes virtually

The digital twin runs thousands of "what-if" scenarios nightly, optimizing tomorrow's production schedule based on: - Predicted equipment availability - Incoming parts inventory - Worker shift patterns - Energy prices - Customer order priorities

Siemens MindSphere

Siemens' IoT platform creates digital twins for entire industrial systems: - Power plants optimizing turbine efficiency in real-time - Rail systems predicting track maintenance needs - Building management systems reducing energy use by 30% - Manufacturing lines self-optimizing for quality and throughput

The platform processes 60 billion messages monthly, each contributing to increasingly accurate world mirrors.

Shell's Predictive Maintenance

Shell uses digital twins across its refineries to: - Predict equipment failures weeks in advance - Optimize process parameters for yield and quality - Simulate upset conditions for operator training - Plan turnarounds with minimal downtime

One refinery reported $10M annual savings from predictive maintenance alone, with unplanned downtime reduced by 45%.

The Architecture of World Mirrors

Data Ingestion Pipeline

Modern world mirrors require robust data pipelines:

Physical World → Sensors → Edge Computing → Stream Processing → Data Lake

↓ ↓ ↓ ↓

Filtering Aggregation Enrichment Storage

Edge Computing: Process data near its source - Reduce latency for critical decisions - Filter noise before transmission - Perform initial aggregations - Enable autonomous operation during network outages

Stream Processing: Real-time data transformation - Apache Kafka for message queuing - Apache Flink for complex event processing - Time-series databases for efficient storage - Real-time analytics engines for immediate insights

The Semantic Layer

The true power emerges in the semantic layer, where raw data becomes knowledge:

Knowledge Graphs: Relationships between entities - Graph databases (Neo4j, Amazon Neptune) storing connections - Ontology management systems defining meaning - Reasoning engines inferring new relationships - Visualization tools making complexity comprehensible

Physics-Based Models: Digital physics engines - Finite element analysis for structural simulation - Computational fluid dynamics for flow modeling - Thermodynamic models for energy systems - Multi-physics coupling for complex interactions

Machine Learning Integration: Pattern recognition and prediction - Anomaly detection identifying unusual conditions - Predictive models forecasting future states - Optimization algorithms finding ideal parameters - Reinforcement learning for autonomous control

The Convergence: CAS Meets World Mirrors

Content-addressable storage provides the perfect foundation for world mirrors:

Immutable Audit Trails

Every sensor reading, every model prediction, every operator action becomes an immutable record: - Content addressing ensures data integrity - Cryptographic proofs prevent tampering - Distributed storage ensures availability - Complete lineage from decision to data

Federated Digital Twins

Different organizations can share digital twin data while maintaining sovereignty: - CAS enables verification without trust - Selective sharing through capability tokens - Federated learning without raw data exchange - Industry-wide optimization while preserving competitive advantage

Temporal Synchronization

World mirrors must maintain temporal consistency across distributed systems: - Content-addressed event logs provide ordering - Merkle clocks ensure causality - CRDT-based state reconciliation handles conflicts - Eventually consistent world models converge to truth

Challenges and Frontiers

The Simulation Gap

Even perfect sensor data can't capture everything: - Unmeasured variables affect outcomes - Chaos theory limits prediction horizons - Model assumptions may not hold - Black swan events defy historical patterns

Solutions emerging: - Uncertainty quantification in predictions - Ensemble models capturing multiple scenarios - Real-time model updating from observations - Human-in-the-loop for critical decisions

Privacy and Security

World mirrors contain incredibly sensitive information: - Complete operational knowledge of critical infrastructure - Competitive advantages encoded in processes - Personal data from workers and customers - National security implications for critical systems

Approaches being developed: - Homomorphic encryption for secure computation - Differential privacy for aggregate insights - Zero-knowledge proofs for verification - Federated learning for collaborative improvement

Standardization and Interoperability

The industry lacks common standards: - Proprietary data formats limit integration - Vendor lock-in prevents optimization - Incompatible ontologies hinder collaboration - Regulatory frameworks lag technology

Initiatives underway: - Digital Twin Consortium defining standards - ISO 23247 for manufacturing digital twins - Industrial Internet Consortium reference architecture - Open source implementations lowering barriers

The Future: Autonomous World Mirrors

The trajectory is clear: world mirrors will become increasingly autonomous, making decisions and taking actions with minimal human intervention:

Self-Optimizing Factories

Factories that continuously improve themselves: - Production lines reconfiguring for new products - Quality systems learning from every defect - Energy systems responding to grid conditions - Supply chains adapting to disruptions

Predictive Infrastructure

Cities with infrastructure that maintains itself: - Bridges scheduling their own inspections - Power grids balancing supply and demand - Water systems detecting leaks before breaks - Traffic systems optimizing flow in real-time

Collaborative Optimization

Industries optimizing together: - Suppliers synchronizing with manufacturers - Logistics networks self-organizing - Energy systems coordinating across regions - Circular economy loops closing automatically

Conclusion: The Mirrorworld Emerges

We stand at the threshold of the Mirrorworld—a complete digital reflection of physical reality. Every factory, every vehicle, every building will have its digital twin, continuously updated, perpetually optimizing, increasingly autonomous. These world mirrors don't just observe; they predict, control, and improve the systems they represent.

The combination of massive sensor deployments, advanced analytics platforms like Palantir's Foundry, and emerging technologies like content-addressable storage creates the foundation for this transformation. As these digital twins become more sophisticated, the boundary between physical and digital dissolves. The factory floor and its digital twin become one entity, inseparable and interdependent.

This isn't science fiction—it's happening now in advanced manufacturing facilities, smart cities, and critical infrastructure worldwide. The organizations that master world mirrors will have an insurmountable advantage: perfect information, optimal decisions, and the ability to see the future before it arrives. The question isn't whether to implement digital twins, but how quickly you can build your world mirror before competitors build theirs.

The Mirrorworld is coming. Those who embrace it will thrive. Those who ignore it will find themselves competing against opponents who can see around corners, predict the future, and optimize reality itself.